Compressed air is one of the three highest cost utilities in use at your plant. It is also one of the least maintained in terms of system leaks. Leaks are expensive and wasteful, but most often ignored. Leaks may occur anywhere in your compressed air system. Here’s our list of top ten most common leaks:

- Connections on air supply lines (pipes)

- Quick couplers

- Filters

- Pneumatic cylinders

- Pressure regulators

- Air dryers

- Isolation valves

- Control valves

- Automatic drain traps

- Air separators

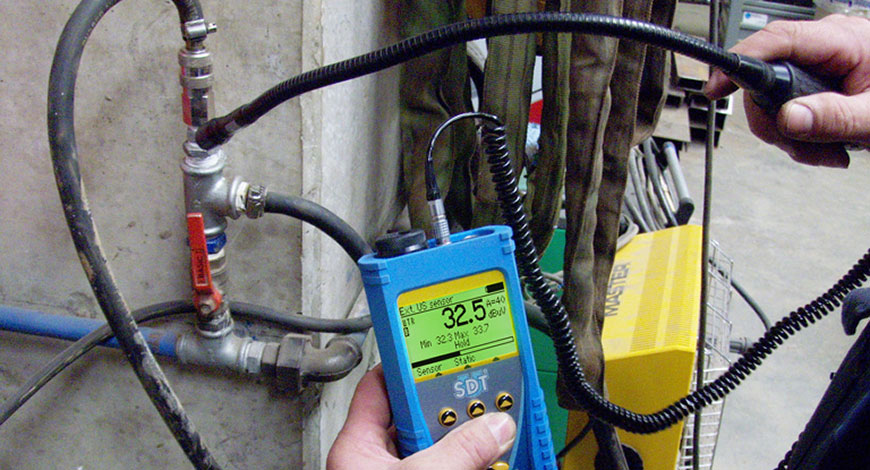

Finding and fixing these leaks is an easy way to reduce energy costs, but finding them is not easy because of background noise. A good quality ultrasonic detector can hear turbulence despite the ambient noise of the factory floor.

Download our LEAK SURVEYORS HANDBOOK and learn how to reduce or eliminate wasted compressed air with ultrasound through effective leak detection and repair.

Source: Ultrasound Leak Surveyor’s Handbook by SDT International.

Filed under:

Maintenance Tips, Ultrasound by Dave Leach CRL CMRT CMRP