The diesel engine is the heart of heavy construction equipment and replacement costs are in the millions. Ingress of dust due to leaky air intake systems shreds components in short order. The SDT TIGHTChecker quickly and easily pinpoints leaks in the air intake system.

Dust is no friend to a diesel engine. But when the integrity of the air breather and turbocharger is compromised by leaks, microscopic grains of silica and other contaminants are sucked inside. There, they wreak havoc on the engine’s internal components costing organizations millions of dollars in premature wear and downtime.

Worse yet, you may not even realize you have dust ingress unless you are conducting regular oil analysis. These leaks are nearly impossible to find using conventional methods. A visual inspection takes hours and is often unsuccessful. Production does not have the patience to wait. They need that asset back in the field, leaks or not.

But what if there was a way to identify those leaks in minutes, instead of hours? SDT Ultrasound Solutions teamed up with mining giant Rio Tinto in Labrador, Newfoundland to devise a simple procedure for identifying turbo leaks in the engines of their huge loaders.

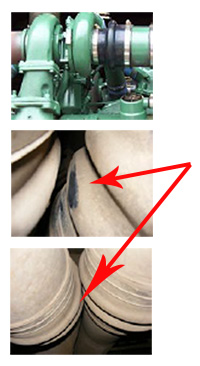

Using SDT ultrasound technology, a transmitter is placed inside the air filter basket. The high-frequency sound waves are contained inside the piping unless there is a leak. Any microscopic air gap in the pipe is instantly recognized by the handheld flex ultrasound detector.

An 8-hour inspection that often ended in frustration is now a worldwide success story that continues to save Iron Ore Company of Canada $8 million per year.

Filed under:

Maintenance Tips, Ultrasound by Allan Rienstra - SDT Ultrasound Solutions