Oil data reports made available by laboratories to their customers are usually delivered in MICROSOFT EXCEL® files or text files. The data is generally made available via an online download. These reports contain information on many different substances found in the oil such as iron, aluminum, copper, and many more. Other factors such as viscosity are included as well.

Oil analysis data provides a great insight into the health of your equipment and should be a routine part of any good reliability program. It can be overwhelming to process all this data in a meaningful way. You may not wish to trend and alarm on every single parameter contained in the oil report. So what do you do? The answer may be your vibration analysis software!

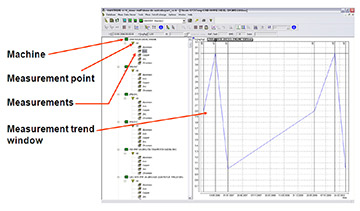

A good vibration analysis program like OMNITREND will allow you to create customizable imports for your oil analysis data. A routine and automated process can be set up to import only the data of interest for specific machines. Once the data is imported, then automated alarms can be created to alert you of any oil parameters that are of concern for your equipment.

Oil data can be visually trended over time and you will automatically be alerted when an oil parameter reaches a value of concern for a specific machine. This can allow you automatically manage selected oil parameters of concern and greatly reduce the amount of time required to manually review each parameter measured by your oil analysis lab.

Furthermore, it will allow you to use the routine vibration data collected and oil analysis data provided by your laboratory to detect and confirm equipment problems. You should not underestimate the power of having your vibration and oil analysis data integrated.

Filed under:

Maintenance Tips, Vibration Analysis by Ana Maria Delgado, CRL