While we’ve been using calendars and calculators to determine grease replenishment requirements in bearings for a long time, this science is wrong. Most bearings never reach their L10 engineered life, and poor lubrication practices are attributed as the primary failure cause.

Bearings fail when they are over-greased. We lubricate them too often, and we use too much grease.

Change Your Thinking.

We lubricate bearings to manage friction, but over time, grease gets old and needs replenishment. The first sign is when friction levels increase. Ultrasound performs well at sensing and measuring changing in friction levels. It’s the perfect technology to guide lube technicians during the lubrication-replenishment task.

Lubrication Solution

We want to grease bearings correctly. That means using the right grease, at the right location, following the right procedures and intervals, injecting the right amount, and receiving the right feedback when the task is done. New technologies from SDT are engineered to do just that.

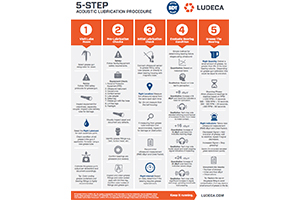

The days of relying on calendars and calculators are over. Use our 5-Step Acoustic Lubrication Procedure and start greasing bearings the right way!

Download our Ultrasound Lube Technician Handbook to learn more!

Filed under:

Lubrication, Ultrasound by Allan Rienstra - SDT Ultrasound Solutions