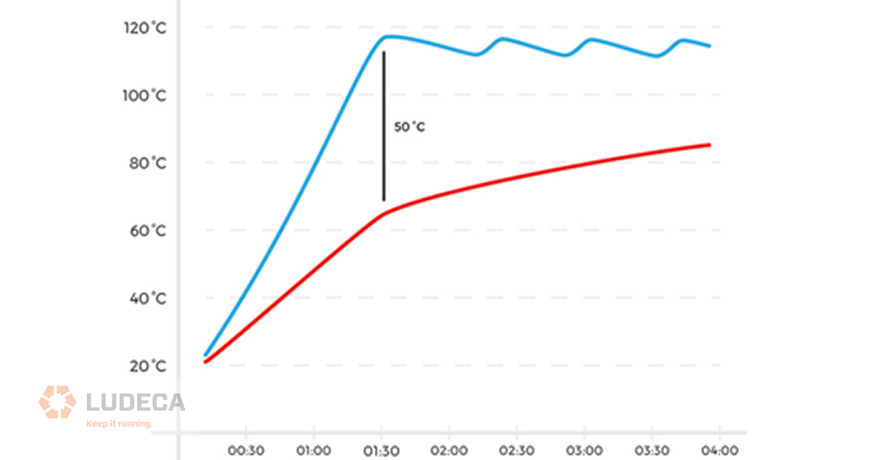

Traditional induction heaters only offer one temperature probe, to monitor the temperature of the inner diameter (ID) of the bearing being heated, assuming that both the inner diameter (ID) and outer diameter (OD) will heat evenly. However, the ID heats faster than the OD, potentially causing stresses between the ID, OD, and the rolling elements. This stress can lead to cracks, fractures, pitting, and deformation of the rolling elements, which can reduce the lifespan of the item being heated. These issues can go undetected, especially in high-precision bearings, where tolerances between the rolling elements and the ID/OD are tight. Even with sprockets and gears, the stress between the ID and OD can produce cracks and fractures in the membrane between them.

Figure 1 – illustrates how the ID heats faster than the OD when a single probe is used. The blue line is the ID and is measured by the temperature probe.

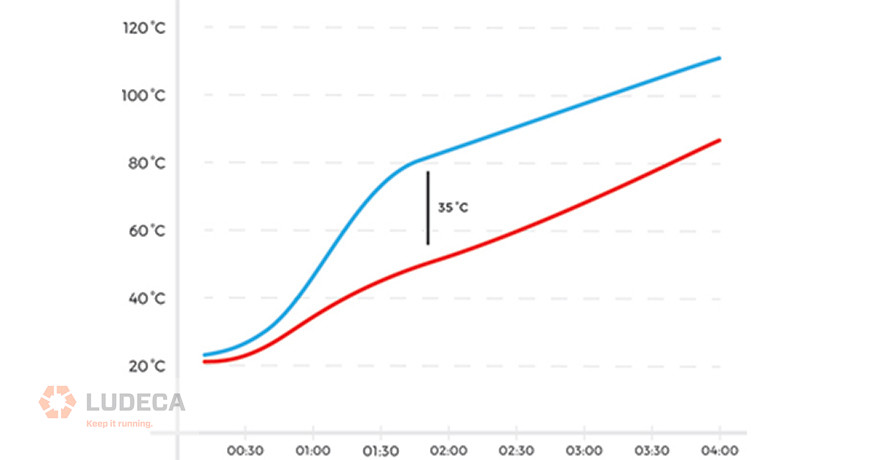

Using a single temperature probe, preventing these issues would be nearly impossible. Therefore, the solution is to use two temperature probes, with one measuring the temperature of the ID and the other measuring the temperature of the OD, simultaneously. The induction heater must be smart enough to adjust the heating cycle when the temperature differential threshold is reached, which is the maximum allowable difference between the IDs and ODs temperatures. This ensures that the desired temperature is eventually reached at the ID while preventing the max difference from being breached, thereby protecting the structural integrity of the workpiece.

Figure 2 – shows how monitoring both the ID (Blue line) and OD (Red line) temperatures together allows more even heating to be achieved.

In conclusion, not all applications require the use of two temperature probes. However, when it comes to preventing harmful stresses created during the heating of a bearing, it is essential. Having an induction heater that possesses this capability to reduce stress on your bearings and other workpieces is crucial. It not only improves the lifespan of the items being heated but also ensures better performance and safety of the assets that these components are mounted in.

Download our Basics of Induction Heating white paper to learn the basic principle behind induction heating, the diverse range of applications and advantages, and the different types of equipment you can use to reach your goals.

Filed under:

Induction Heating by Bernd Seidenthal CRL