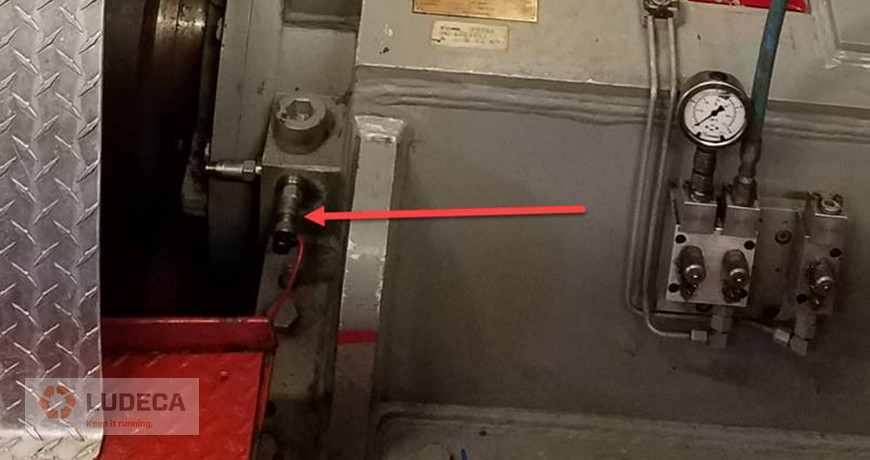

Below is a short list of when someone should consider using permanently mounted vibration sensors. This scenario would involve either epoxying on the vibration sensors or drilling into the equipment to allow for the sensor to be physically attached to the equipment. A vibration cable is then attached to the sensor and terminated into a junction or switch box. The junction or switch box can vary on the number of points that need to be collected. Once the cables are terminated into the junction box the analyst can collect data directly from the junction box.

Please note a handheld vibration collector like our VIBWORKS portable vibration data collector, would need to be connected to the junction box to collect vibration data from the permanently mounted sensors.

- Safety – Some equipment can be dangerous to be near

- Saves time – Some equipment can be mounted in hard to reach places

- Avoid hazardous environment – The junction box can be mounted outside the hazardous area

- The first phase of an online deployment – The installation, sensors, and cables are a large cost in any online project. A Cortex online system can be added later to replace the junction box.

Below is a short list of when someone might not consider using permanently mounted vibration sensors. This scenario would involve either epoxying on the vibration sensors or drilling into the equipment to allow for the sensor to be physically attached to the equipment. A vibration cable is then attached to the sensor and terminated into a junction or switch box. The junction or switch box can vary on the number of points that need to be collected. Once the cables are terminated into the junction box the analyst can collect data directly from the junction box.

Please note a handheld vibration collector like our VIBWORKS portable vibration data collector, would need to be connected to the junction box to collect vibration data from the permanently mounted sensors.

- Cost – Multiple sensors and cables can become expensive

- Time – Installation of the sensors, cables, junction boxes, and conduit

- Loss of human interaction – The analyst cannot use their senses (sight, hearing, and touch) as they are not near the machines

- Damaged cables or sensors – Sensors dislocated and cables cut

Do you have any pros or additional cons to using permanently mounted sensors? Do you have any images of junction boxes that are currently in use or comments on why permanently mounted vibration sensors would not function for your applications? Please share those with us!

Filed under:

Condition Monitoring, Maintenance Tips by Mickey Harp CRL