All machines and their components will exhibit wear at some point. This can lead to loss of function and require corrective action.

Wear particles are one of the most common sources of equipment reliability problems. They indicate that the oil is unfit and unreliable for operation in the equipment and will lead to damage to the equipment. These particles can give an insight into the type of equipment problems as well. The characteristics of wear are specific from machine to machine.

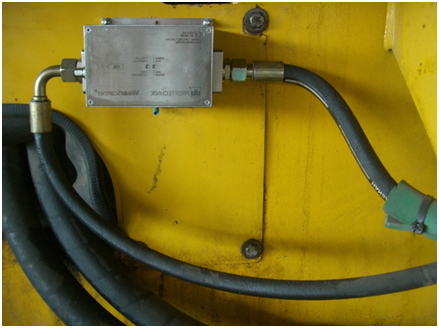

A facility in Texas lost key personnel in their condition monitoring program and experienced a gearbox failure. The plant was in need of a true online monitoring system for small and large particle quantities. They purchased the WEARSCANNER® oil particle distribution solution as a result. The WEARSCANNER solution not only counts and classifies but also has the ability to count low and high particle flow speeds which is of value to the customer.

The customer was able to adjust the different size classes in accordance with ISO 16232 and have the data fed directly into their control system.

One of the keys to equipment reliability is keeping lubrication clean, cool, and free of moisture. This facility purchased the WEARSCANNER solution so they can actively monitor the cleanliness of critical equipment.

Filed under:

Condition Monitoring, Lubrication, PDM by Alex Nino CRL