In the wastewater treatment industry, uninterrupted aeration is crucial for effective operation and compliance with environmental regulations. When a Wastewater Treatment Plant (WWTP) experienced a major bearing failure in two of their high-speed, high-temperature blowers, it posed a significant challenge. The blower manufacturer had no spare parts or replacements available, leaving the plant at risk of EPA issues and costly downtime. This case study highlights how the implementation of Sensoteq’s KAPPA X wireless monitoring solution provided crucial support, proactive maintenance, and prevented further damage to critical equipment.

The WWTP faced an urgent need to address the bearing failure in their blowers, as it jeopardized their aeration process. With no spare parts or replacement blowers immediately available, they were forced to rent a blower system at a substantial cost while the damaged blowers were being rebuilt. The plant’s time-sensitive operations demanded a reliable monitoring system that could alert maintenance personnel to potential issues before catastrophic failures occurred.

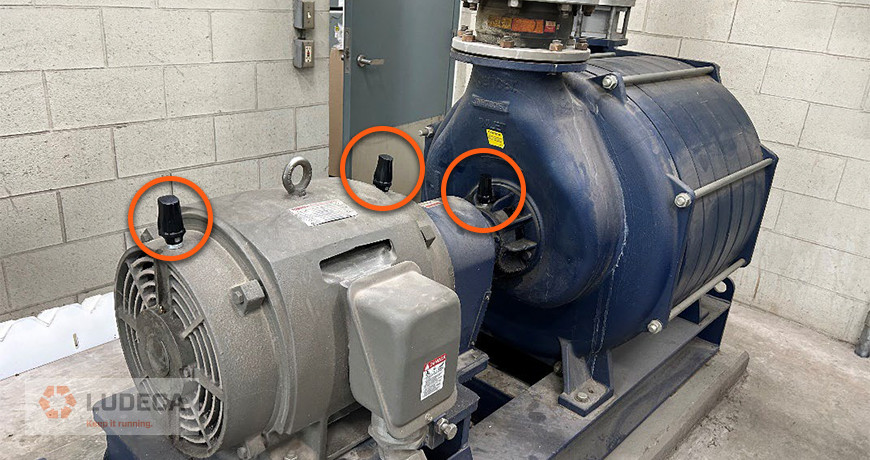

Recognizing the importance of continuous support and 24-hour monitoring, the WWTP turned to LUDECA for a solution. The KAPPA X wireless vibration monitoring system was chosen for its ability to set thresholds and alarms, providing real-time notifications of any abnormalities by email or SMS text. This would enable the plant’s maintenance team to promptly respond, shutting down units before secondary damage occurred. The implementation of the KAPPA X system allowed for proactive maintenance practices and ensured the integrity of critical equipment.

Click here to continue reading this case study and find out the benefits in using our KAPPA X wireless vibration monitoring system!

Filed under:

Condition Monitoring by Alex Nino CRL