In today’s world-class facilities, maintenance and reliability departments require data collection on a consistent and periodic basis to guarantee that assets in a plant operate efficiently and reliably.

Vibration monitoring actively monitors the health of critical assets for potential failure conditions. This yields great results in identifying potential failure conditions for repair before unwanted downtime or other costly consequences are experienced.

Typical walk-around vibration programs can take time to establish and get going, whereas online condition monitoring can be expensive due to the installation costs including labor, cables, sensors, etc. Moreover, a cabled installation might even be impossible in certain situations due to accessibility issues.

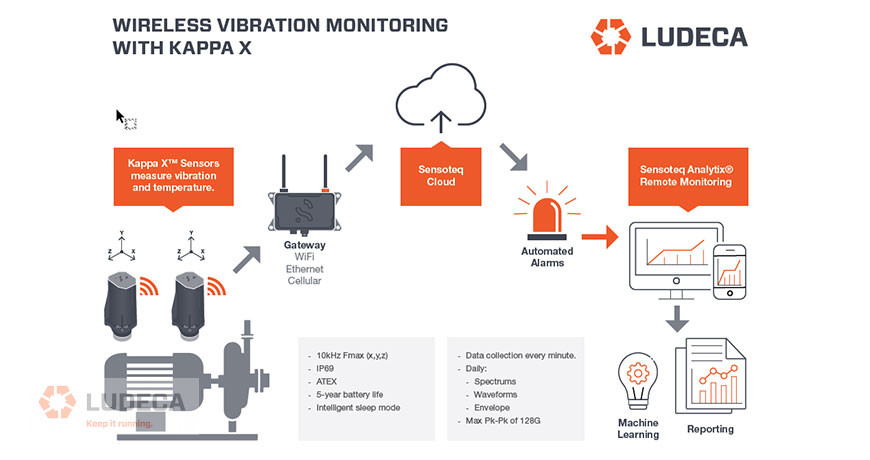

On the other hand, an IoT solution such as wireless technology can solve all of these problems and is an ideal solution for most facilities. Having a wireless vibration program with smart sensing technology is cost-effective for all manufacturing applications. A wireless vibration solution such as the Sensoteq Kappa X with prolonged battery life, a Fmax of 10kHz, and 6400 lines of resolution with signal analysis with enveloping can provide unparallel level of diagnostic capabilities and asset health monitoring of your plant machinery.

Data can be viewed from anywhere in the world and you can be notified of any issue arising in your assets via either a PC or mobile device, and the data can also be seamlessly entered into your facility’s PLC or DCS system.

Filed under:

Condition Monitoring, Vibration Analysis by Alex Nino CRL