In the world of vibration analysis frequency is everything. Frequencies are generated by many sources within a machine. The running speed of the machine is one example frequency; this is the velocity of the rotating element which in many cases is a drive shaft connected to an application (like a fan or a pump). Each frequency will have a magnitude associated with it; this is the total amount of energy of that specific frequency. The amount of energy of any given frequency can tell us a lot about what is going on within a machine. When we use a vibration sensor to measure a machine, this is what we are detecting, frequencies, and magnitudes of those frequencies.

The maximum frequency that a sensor can measure is called the Fmax. This value lets the user know what type of faults they can detect on a machine. It is typically listed in hertz (Hz). The higher the Fmax value, the greater number of faults that a sensor will detect, but it will also allow for earlier indication of potential faults, like a bearing failure. Some ISO standards will reference a Fmax of 1kHz – whilst taking a reading up to 1kHz is suitable for most acceptance testing, it will not highlight even the most basic of bearing faults. A minimum of 2.5kHz Fmax is recommended for good coverage.

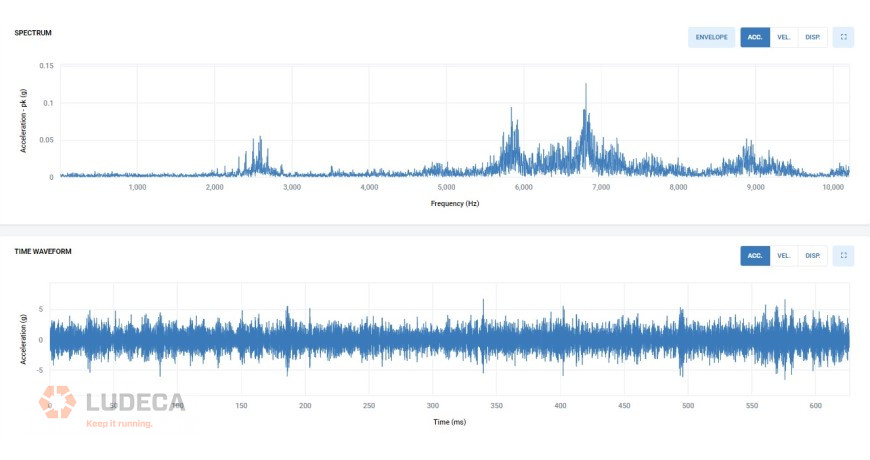

Recently, a new sensor has entered the market that boasts a Fmax up to 10kHz. This Fmax gives great coverage for a wide variety of faults, and will accurately inform users of issues on complex equipment like gearboxes that have many higher fault frequencies. In addition, a higher frequency will give an earlier indication of bearing faults. Bearing failures will typically start within the subsurface of the metal with a very small amount of energy being emitted to the sensing element, thus having a sensitive measurement device with the right Fmax is critical to understanding the health of your machine early, prior to failure impacting any processes or causing downtime.

Thank you David Procter with Sensoteq for sharing this educational article with us!

Filed under:

Condition Monitoring, Vibration Analysis by Diana Pereda