Certain technologies have been used for a very long time to identify corrective actions required to keep equipment operational and reliable. Vibration analysis, ultrasonic monitoring, infrared thermography, motor condition evaluation, and lubrication analysis are examples of these technologies. Many terms have been used to describe their usage within a facility. One term often used is “Predictive Maintenance”. Unfortunately, this term can be used in the literal sense with dire consequences.

Many facilities mix all of the required ingredients together to create a successful maintenance and reliability program. Regrettably, many others fail in their efforts. Two of the primary elements for success are predictive maintenance and work execution. The predictive maintenance effort may be quite effective at identifying conditional changes in equipment that should be addressed before functional failures occur. Those efforts will not be fruitful if the results are not executed. The predictive maintenance team has to generate work that is planned, scheduled, and executed. If the results of their efforts are not executed, then the facility will plainly predict costly failures that will be experienced by the facility. Basically, the effort will shift from “Predictive Maintenance” to “Predictive Failures”.

Make sure your facility is not predicting failures. Make certain the results of the predictive maintenance technologies are executed before conditional changes result in equipment failures.

by Trent Phillips CRL CMRP - Novelis

Machine components are susceptible to premature wear and corrosion due in part to the harsh environments they are placed in. To combat this, here are a few suggestions to keep your machines running:

- Proper lubrication

Always make sure the movable components in the machine are getting the lubrication they need. Lubrication not only keeps parts cooler and moving freely but also prevents corrosion. - Cleanliness

Keep the machine components as well as their environments as clean as practical. This can aid in preventing wear stemming from particle ingression and friction. - Keep logs

Keep a log of all the PM (preventative maintenance) done on your machines so as to avoid duplication and prolong the life of its components.

If you follow these simple guidelines, it will help prevent breakdowns in your plant and save money.

by Oliver Gibbs CRL

The scenario: You have just been informed that a corporate reliability initiative has begun. Your new assignment is to implement a vibration analysis program. You are disconcerted because you are not sure how to implement this new assignment or where to seek help. Many organizations implement a reliability initiative because their competition has already done so or management has become convinced of the financial value that can be gained from it. Unfortunately, as with most things in life, the devil is always in the details.

Company culture plays a critical role in the successful implementation of a reliability program. This shouldn’t be underestimated. Some companies implement program after program, each with the best of intentions. The objectives are always to increase operating efficiencies, achieve cost reductions, capacity improvements, shrink required manpower, etc. Many of these efforts fail after a few months because the program is replaced by something new, key management individuals did not support it, inadequate funding was provided, proper awareness was not instilled, and many other reasons. The new initiative falls into an abyss and is quickly forgotten.

Most seasoned employees who work in these organizations have seen this happen time after time over their careers.

Many employees and managers thus adopt a “wait and see” approach. This trait is learned after years of seeing efforts start and quickly fail. Why join the “flavor of the month” club and devote focus to something that will soon be replaced? It requires less energy to wait and see if the new program will remain a company priority and become successful. The financial value to your business is clear, but will only be realized if the program is correctly implemented and sustained. Senior management has to ensure that everyone understands this effort is not a passing fad. Key signs of support must be given with results-driven implementation.

Don’t let the vibration analysis program and other reliability efforts become a “flavor of the month” effort.

Become the champion that promotes the value of these efforts and helps to ensure the results are implemented.

Doing so can reap great rewards for yourself and pay great dividends for your company. Seek support and advice from technology vendors, co-workers, and the many resources available. You are not alone! Many individuals have been where they are now or faced the same challenges within their organization.

The road to success can be long and difficult to traverse. However, with proper implementation, persistence, and senior management support you can get there. Persevere!

by Dave Leach CRL CMRT CMRP

Have you considered the costs associated with allowing your equipment to continue operating at excessive vibration levels? Have you considered the benefits of reducing the vibration levels of your equipment? The reliability and cost benefits of reducing the vibration levels of your equipment may surprise you.

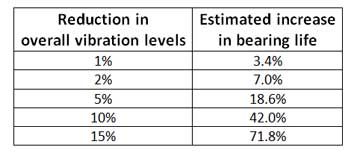

Below are some examples showing the estimated increase in bearing life attainable by reducing the overall vibration levels in equipment.

Do not deny your facility the increased equipment reliability and decreased maintenance cost associated with reductions in vibration levels.

by Trent Phillips

Why does so much ‘stuff’ fall between the cracks that exist between data and information. So often we see a highly trained analyst with a tremendous amount of data working with a manager who takes very little information from the data. There is obviously a communication breakdown but who is to blame. Is it the analyst for not clearly interpreting what the data –the squiggly lines– are telling us? Or is it the manager’s fault for not understanding what he’s seeing. The reality is that the fault lies with both of them.

I know of some analysts who believe that their role is to take readings and supply them – with a little interpretation- to the maintenance manager. I also know some maintenance managers who when faced with this situation merely file away the reports. Obviously, neither is right but neither has bothered to take the time to make sure that they clearly understand what the purpose of the whole exercise is.

As a plant maintenance manager, I didn’t know the intricacies and nuances of spectrum analysis or waterfalls or acceleration enveloping – I didn’t need to! That’s what the analyst was there for, but what I did need to do was communicate clearly to the analyst what it was that I wanted from the exercise. For me it was fairly simple – I needed to have enough information to make a more informed decision. That is really the purpose of any measures that we make so I always made a point of clearly explaining this to the analyst. I needed to know if there were any imminent failures or if there were dramatic changes in the trends, what the implications of the changes were, and how fast the deterioration was taking place (even though we call it predictive maintenance, exact predictions are very difficult).

The analysts I liked working with were the insistent persistent ones – the ones who would not leave until they were sure I got the message. Many people would have considered them a pain – but they were the ones I wanted on my team as they felt the same sort of ownership that I did. I guess that’s the key to it all – ownership – as along with the ownership, there is the pride and success that you share with every good call with every failure mitigated. But this only happens when there is clear communication of the purpose, goals, and expectations. So don’t forget – Communicate, Communicate, Communicate

Thanks to Cliff Williams, Author of People – A Reliability Success Story, for sharing his expertise with us.

by Ana Maria Delgado, CRL

We have a strong focus on our predictive maintenance training program of which laser shaft alignment and vibration monitoring play a very important part for us and all the local manufacturing businesses that we serve. Using LUDECA’s support and more intuitive tools like the SHAFTALIGN® and the VIBXPERT® we find that we can better prepare our students in ways that we could not accomplish before. Our purpose here is to prepare our students for all of the new challenges in the predictive maintenance field and LUDECA helps us accomplish our goal.” —Bert H, Central Carolina Tech

by Ana Maria Delgado, CRL

You’re 17 times more likely to introduce defects during equipment startup than during normal equipment operation. Additionally, over 90% of rotating equipment has defects at startup that result in premature equipment failures.

Misalignment and unbalance are two of the most commonly overlooked conditions that lead to the unwanted statistical results referenced above. Misalignment in equipment leads to increased vibration levels, bearing failures, coupling wear, seal failures, shaft fatigue, increased power consumption, and other negative effects.

Unbalance in equipment can introduce structural related issues, bearing defects, and other issues. Both conditions can create unwelcome safety concerns. Additionally, both conditions can be present on the same equipment, and working in concert can, unfortunately, amplify the referenced failure conditions.

So, how do you prevent misalignment and unbalance conditions from making your equipment part of these negative statistics and placing your company at financial risk? The answer is to apply condition monitoring technology and procedures such as laser alignment, equipment balancing, and vibration analysis to your equipment. These condition monitoring activities will lead to reduced equipment downtime, reduced equipment failures, improved safety, reduced financial risks, increased equipment uptime, lower operating costs, and increased profits for stakeholders.

by Trent Phillips

Simple Defect Elimination

PUMPS & SYSTEMS • July 2013

Defect elimination is a simple maintenance strategy with seemingly obvious value. However, how many facilities pursue it to the greatest degree of value? According to Webster’s online, a defect is “an imperfection that impairs worth or utility.”

The “utility” part of the definition is significant because every process industry professional focuses on uptime. If a machine has a defect, but it still works (still makes widgets) and that machine imparts defects into the widgets, the worth of that widget is reduced. Or if the machine still works, but production is slowed, the number of widgets produced over time is reduced. The worth of widgets sold is also reduced.

Defects cost money. If end users candidly investigate, they may see that they are investing money in keeping their defects. How? Money lost because the widgets are being sold at a reduced price or because the maximum number of widgets were not manufactured because of slowed production or downtime is money invested in keeping defects. Even worse, some operators are on long-term payment plans for their equipment, so they continue to invest in the same defects year after year.

The second part of the definition is elimination. According to Webster, eliminate means to put an end to or get rid of. The absence of a defect also means the absence of the investment required to sustain the defect. An asset that is free of defects is an asset that can be optimally profitable. Defect elimination usually requires an investment. Rarely does simply tightening a bolt or performing an equally trivial task fix an expensive problem.

Read my entire article Simple Defect Elimination at Pumps & Systems

by Mike Fitch CRL

Every organization claims they have procedures or “checklists” to eliminate self-induced failures or missed steps but are they followed? Are they accurate? Are they written to a sufficient level of detail? Have they ever been reviewed? Do we know the difference and when to use them?

A checklist is a type of informational job aid used to reduce failure by compensating for potential limits of human memory and attention. It helps to ensure consistency and completeness in carrying out a task. Checklists are appropriate for vehicles, mobile equipment, equipment set-ups, equipment or line starts and stops, etc.

A procedure specifies a method for performing a task, it is written to a specification. A procedure is designed to describe who, what, where, when, and why by means of establishing accountability in support of the implementation of that specification. The “How” is further documented in the form of work instructions which further support a procedure by providing a greater level of detail. Procedures are appropriate for Preventive Maintenance (PM), Predictive Maintenance (PdM), equipment rebuilds, refurbishments, or overhauls, corrective maintenance activities, etc.

Both can and should be utilized in support of maintenance activities where applicable.

Thanks to Dave Bertolini with People and Processes, Inc. for this great tip.

by Ana Maria Delgado, CRL

Engage, support, train, provide direction, and set goals for those involved in the Condition Monitoring (CM) effort. Otherwise, they will most likely make poor decisions on your behalf. Unfortunately, most reliability efforts fail. This can be due to a change in management focus and the lack of importance placed on reliability efforts such as Condition Monitoring. Management has to demonstrate consistent signs that reliability efforts are important to the overall business goals of the company and ensure that the results of those efforts are continually implemented.

It is important to create realistic expectations! Understanding the value and limitations of the CM technology is important as well. Make sure that data collection and analysis activities are completed at the correct intervals to detect conditional changes in the equipment being monitored and that the findings are properly documented.

It is critical to ensure that the recommendations of the condition monitoring technology are implemented. It serves no purpose to generate findings that will maintain and/or improve equipment health and not implement the results (do the recommended work). Do not make the CM program a “part-time effort”. Doing so will almost guarantee the failure of the effort.

Design, installation, startup, and the operation of the equipment are the biggest contributors to reliability or lack of reliability within a plant. Engineering, maintenance, production, and reliability efforts are interdependent. Collaboration is important between these groups and Management has to promote this effort. CM efforts create reliable capacity. Plant capacity is not of much use if it is not reliable! It is important that CM efforts be integrated into all of these areas. Additionally, it is important to make sure that considerations are taken when purchasing and maintaining spare parts. This process can have a great impact on equipment reliability.

What tips do you have so that Managers can have a successful Condition Monitoring program within their facility?

by Trent Phillips