Sometimes unbalance can be caused by a shaft key being too long. When a shaft assembly goes to the balance machine, the assembly is normally balanced with a half key installed. The coupling and key have been removed and a half key installed into the keyway on the shaft. The straight portion of the shaft keyway is filled with a piece of steel; however its height is ground down so that it closely matches the outer radius of the shaft. In other words, it doesn’t stick out!

Electrical tape is then wrapped around the half key and shaft so that the half key doesn’t come flying out during the balancing operation. After the rotating assembly has been successfully balanced to within tolerance, the rotating assembly is returned to the technician for final reassembly.

In the following example, let’s assume that the actual length of the keyway in the shaft is 8 inches long and 3/8″ deep. The length of the coupling hub keyway is 4 inches long and it is also 3/8″ deep. If the technician installed a key that measured 8″ long × ¾” × ¾” and then mounted the coupling onto the shaft it would result in an excessive key length sticking out past the back edge of the coupling hub. The extra 4 inches × 3/8″ high key stock sticking out behind the coupling could be enough mass to cause the imbalance to exceed ISO balance tolerances.

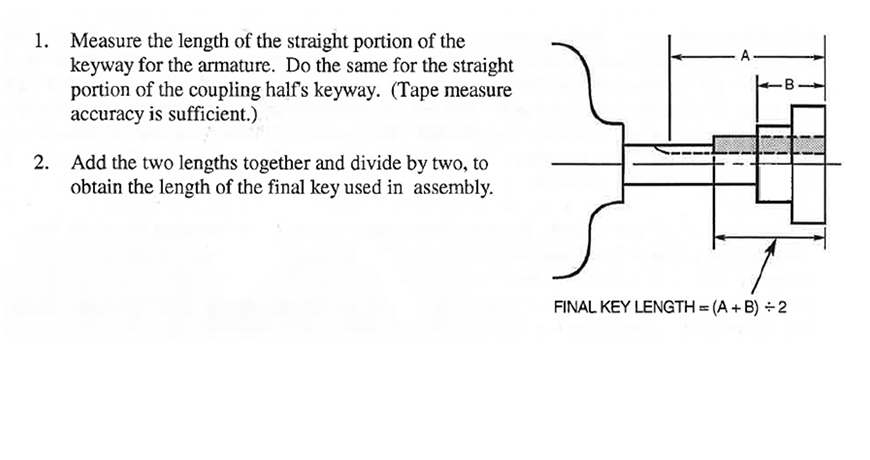

The following method should be used to calculate the proper key length:

Source: Practical Solutions to Machinery and Maintenance Vibration Problems, Chapter 5, Unbalance, Section 16, Unbalance Due to Assembly Errors – Key Length Considerations by Update International

Our advanced field balancers can help you identify, correct and avoid the unwanted consequences of equipment unbalance. For more information, visit our website.

Filed under:

Balancing, Vibration Analysis by Dave Leach CRL CMRT CMRP