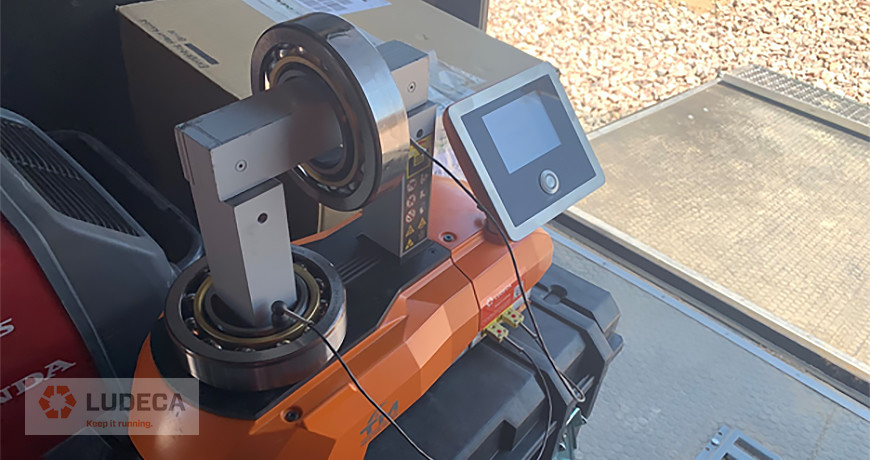

In 2019, JetTech Mechanical LLC was hired to perform maintenance for NGL Pipeline in Colorado. They serviced several SPX Clyde Union Pumps, BB3-D12X12X17W 2 stage 3250 HP, and 3775 RPM, pumping at 7525 US GPM 2000 Ft of Head. Part of the service was to remove and replace the pump’s opposite drive end thrust bearings. The bearings were SKF 7313BECBMs, the installation was back-to-back. To remove the bearings, two jaw pullers were used, and to replace the bearings a SURETHERM 10X induction heater with two temperature probes was used to precisely heat and demagnetize the bearings for installation.

Previously a different portable induction heater had been used, but it took much too long, the heater itself got hot and it only had one temperature probe. The great advantage of the SURETHERM bearing heater is that the twin temperature probes let you precisely monitor the difference between the inner and outer race temperatures and keep that differential to a minimum in order to prevent stressing the bearing.

On the first install, the bearings were heated to 225 degrees Fahrenheit; this took approximately 2 minutes from ambient. The largest possible crossbar that fit the bearing ID was used. One bearing at a time was heated and installed within 6 minutes. No appreciable temperature difference was observed in this case, which gave rise to the greater efficiency experiment we tried next.

The experiment was to see whether on the second installation two bearings could be heated at the same time, placing one bearing around the post and the other on the crossbar, with one probe per bearing. Once again the induction heater worked flawlessly, heating both bearings within 2 ½ minutes and both to the same temperature, 225 degrees Fahrenheit.

This proved to everybody’s satisfaction the full capacity of the SURETHERM induction heater and its efficiency to heat evenly.

The customer’s conclusion was that the SURETHERM is a lot more efficient than any other induction heater they have used in the past. The fact that the Suretherm uses 2 probes, gives them the confidence that the difference in temperature between the OD and ID can easily be monitored making it safe and precise to heat bearings.

They also discovered that they can heat two bearings at the same time, and having the two temperature probe capability allows them to monitor the temperature of both bearings. Even though it is recommended that only one bearing at a time should be heated.

Thank you Brian Franks with JetTech Mechanical LLC for sharing this case study experience with us!

Download our Induction Heating Procedure – Bearing Mounting to learn more about how you can install your bearings properly in a simple and safe way.

Filed under:

Articles and Case Studies, Induction Heating by Bernd Seidenthal CRL