Motion Amplification is a camera-based full-field vibration technology that turns every pixel in the camera into a displacement sensor enabling you to see and visualize motion across the entire video. This opens up opportunities in visualizing an asset or system holistically instead of location by location often revealing information that would otherwise remain hidden. By combining this technology with other precision maintenance tools in the reliability toolbox you can better position yourself to address underlying issues and bring your equipment into a more sustainable operation. It is common for problems with machinery such as motor and pump installations to remain hidden or go undiagnosed.

For example, an improper or insufficient base installation can lead to excessive stress or looseness that ultimately leads to further faults or degradation in operating conditions. High vibration levels can be observed through contact sensors, but the problem persists even after the most common repairs are made, or perhaps the problems soon return. Often these issues are longstanding and go unmonitored and undiagnosed. These persistent issues can make it impossible to align a machine to the specified tolerances. Detecting issues through Motion Amplification can expedite the determination of the root cause issue. Once detected and repaired the equipment can then be precision aligned to bring it into the proper operating conditions and make it better suited to stay in that condition. By leveraging motion amplification and precision alignment technologies together, you can achieve a broader approach to diagnosing equipment and achieve more sustainable alignment conditions knowing the equipment you just aligned is not being affected by a fault still existing in the system. One size doesn’t always fit all and combining multiple tools in your reliability program to achieve superior reliability is just another way you can #keepitrunning.

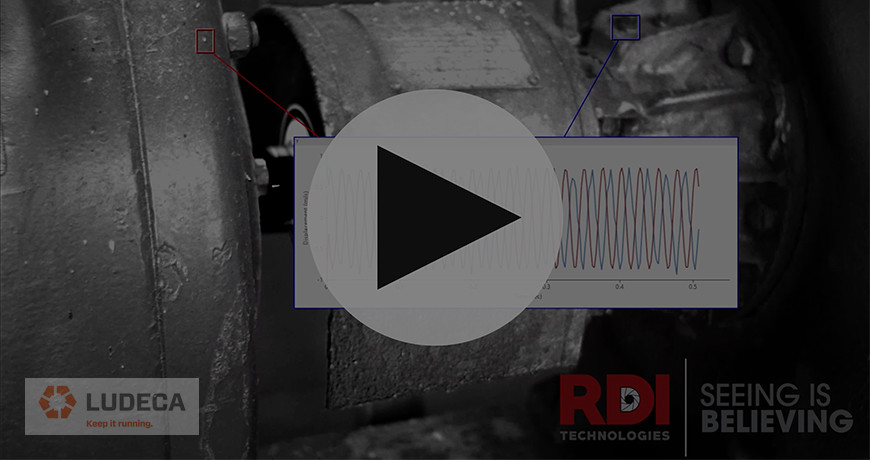

Motion Amplification showing Misalignment – Equipment setup: motor (left) and blower (right). The data on the screen is showing a measurement on either side of the coupling made from the video (red box corresponds to the red plot and blue box corresponds to the blue box) indicating the motion is 180 degrees out of phase in the vertical direction. This is also seen in the Motion Amplification video as one side goes up while the other side goes down.

Motion Amplification can be utilized in a multitude of use cases and to detect a broad number of faults. Among them are:

- Misalignment

- Imbalance

- Looseness

- Soft Foot

- Belt Slippage

- Structural Weakness

- Thermal Growth

- Resonance

- Bent Shaft

- Shaft Runout

- Flow Turbulence

- Excessive Piping Vibration

Thank you Jeff Hay with RDI Technologies for expanding our knowledge about motion amplification technology with us!

Filed under:

Alignment by Diana Pereda