Soft Foot Measurement – It really is important!

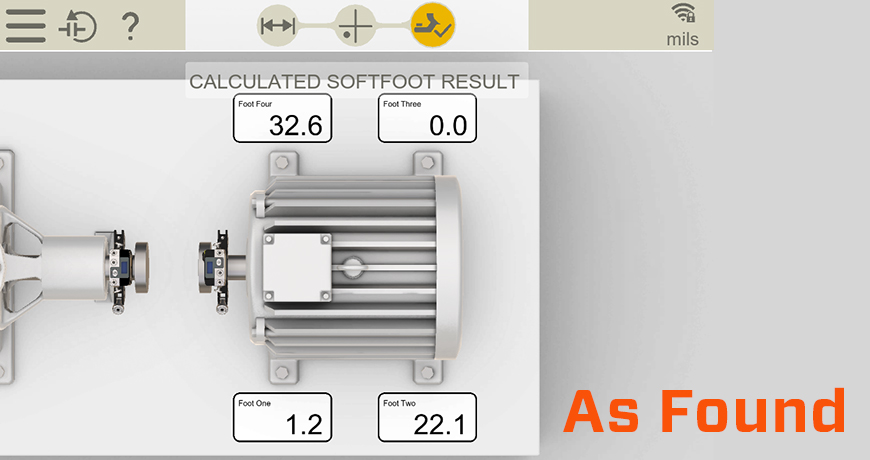

On a recent visit to a power plant, they asked me to help them align a pump with their new EASY-LASER XT Alignment System. It was a machine they had previously aligned with dial indicators, which they thought was “pretty good”. The initial measurement showed a vertical offset of about 7 mils, so we removed all the shims and measured soft foot. The results are shown below.

As you can see, there was a significant issue. We probed and found gaps under both the indicated feet. The foot showing 32.6 mils showed a parallel air gap, whereas the foot showing 22.1 mils had an angular gap that required step shimming.

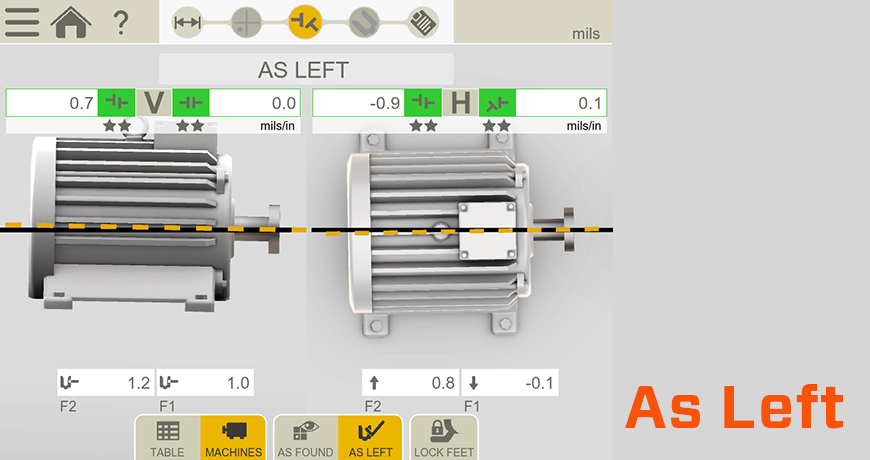

Once the soft foot was corrected we continued with the alignment, and achieved excellent results.

In a later conversation, I learned that the motors had been too high for the pumps when installed, so the contractor ground down the feet with a wheel grinder! That explains the soft foot issue!

Bottom line, ALWAYS check soft foot. Not only does uncorrected soft foot make the alignment more difficult, it introduces stresses to the machine thus reduces reliability.

Download our Soft Foot: Causes, Characteristics and Solutions white paper for additional information that explains in depth the causes and characteristics of soft foot conditions and how to diagnose and solve them.

Filed under:

Alignment by Bob Dunn - I&E Central