Better Running Conditions from Precision Alignment

We performed an alignment as part of a yearly check on a Caterpillar G3606 engine mated to an Ariel JG-D compressor. Documentation was established to track the performance of the equipment before and after the alignment.

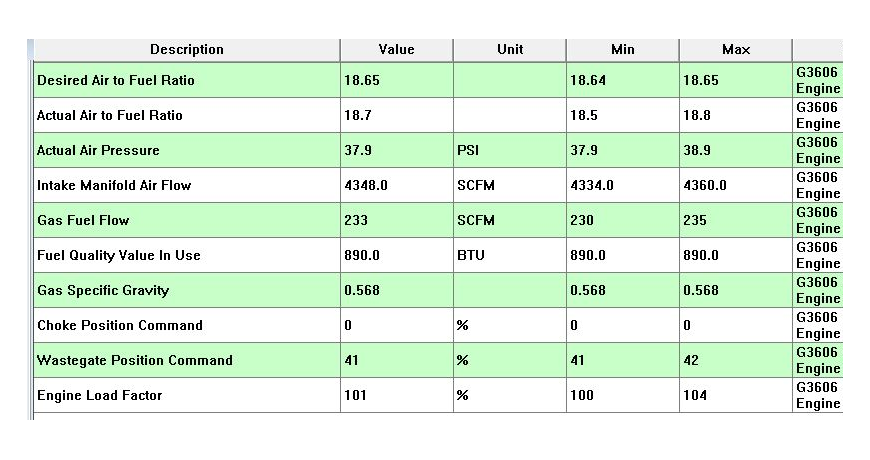

Before alignment:

The engine was running overloaded, consuming more fuel than budgeted, and over the permitted emissions levels. Initial readings found 0.012” of misalignment, and soft foot of 0.005” in a single mounting pad. Correcting the alignment to within 0.004″, using thermal growth targets, and correcting the soft foot, yielded the results needed for better running conditions.

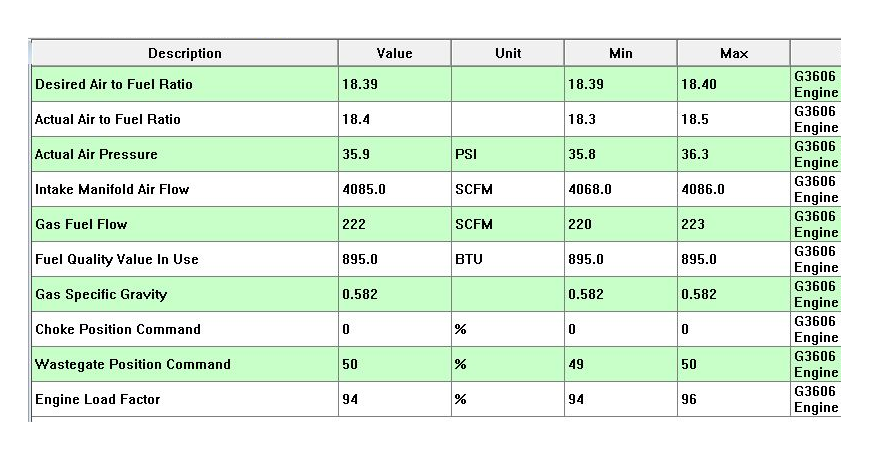

After alignment: Load was reduced by 6%, and fuel flow dropped by 10 cfm (saving $8800 per quarter). Emissions were well within permitted levels. This mitigated the possibility of a fine, which could be up to $33,750 PER DAY of non-compliance. All of these realized gains resulted directly from a precision laser alignment, carried out with precision tools, performed by properly trained technicians, to the standard of excellence required in today’s cost-aware environment.

Load was reduced by 6%, and fuel flow dropped by 10 cfm (saving $8800 per quarter). Emissions were well within permitted levels. This mitigated the possibility of a fine, which could be up to $33,750 PER DAY of non-compliance. All of these realized gains resulted directly from a precision laser alignment, carried out with precision tools, performed by properly trained technicians, to the standard of excellence required in today’s cost-aware environment.

Filed under:

Alignment by Chris Greene CRL