I remember once performing an alignment where I followed the guidelines at the time to make sure no soft foot was present before continuing the alignment. I struggled to take care of the soft foot issue, yet still had unacceptable results. No more than 3-5 shims under each foot? Check. Pull each shim pack with all feet unbolted and fill in obvious gaps? Check. Inspect shims and remove rusted, damaged or crinkled shims? Ah –hah!

At that point, I inspected the shims and found one, a 150 thou shim, to have a slight bow in it due to it conforming to the base. I essentially had a leaf spring under the foot. No amount of shim corrections will eliminate this situation. A leaf spring is a very common suspension component found in trucks and trailers and shown below.

This leaf spring effect manifests itself in two forms:

- The first form is when a very large shim is bent and placed back into the machine foot upside down. This forces the machine foot up when the bolt is loosened during a soft foot check.

- The second form is when there are a stack of more than 5 shims, particularly if they are crinkled or bent. The combination of these defects also creates the leaf spring effect.

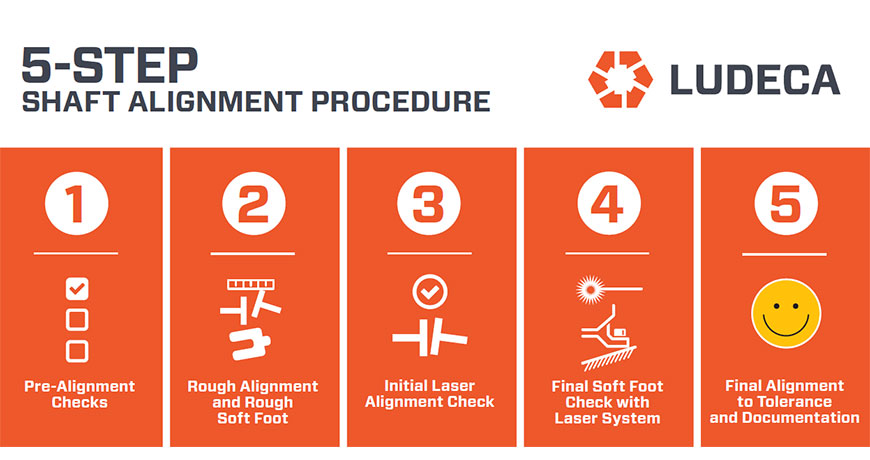

The importance of pre-alignment checks is important in rotating equipment alignment. It is so important that we have incorporated it as step #1 in our standard Ludeca 5-Step Shaft Alignment Procedure as shown below.

The importance of these pre-alignment corrective actions have been incorporated into the ANSI/ASA S2.75-2017 alignment standard. According to the standard:

Shims should be in clean, smooth condition. Used shims should be discarded if the damage is evident. No more than 5 total shims shall be placed under any machine case foot, excluding the shims to correct angle foot conditions. No more than 1 of those shims shall be less than 0.08 mm (0.003 inches) thickness. The sum of the three thinnest shims shall be 0.25 mm (0.010 inches) or greater.”

Removing the soft foot issues is important and fortunately, there is a field-proven solution to make sure these have resulted in the problem being remedied and documented. All Easy-Laser E-series and the latest XT-series alignment systems, incorporate a soft foot check program.

Using .0001” resolution detectors, the shaft movement observed when loosening and tightening each foot can be documented for soft foot analysis and correction. With soft foot remedied, the alignment can now proceed with peace of mind knowing the corrections will be more precise and that internal frame distortion of the machine is eliminated.

Filed under:

Alignment by Daus Studenberg CRL