You’ve always heard the adage, “Laser on the Stationary and Receiver (or Prism) on the Movable.” In this day and age, however, this “truism” has become obsolete. You see, the concept of the “stationary” machine, per se, is obsolete. ALL machines CAN be moved if they really need to be (no machine grew out of the ground, like a tree!), so instead, we emphasize that the laser should be mounted on the machine that is “more difficult” to move (usually the pump because of the connected piping.)

The flexibility that all ROTALIGN® (and OPTALIGN SMART® products) offer through their static feet function, as well as the ability to freely flip or rotate the view of the machines to suit your needs, means that you no longer need to concern yourself with “stationary” machines. Your real goal is to find the easiest and most expedient way of aligning your machines. In some cases, this may mean moving one pair of feet on the pump just a little to keep from having to move the motor feet a lot.

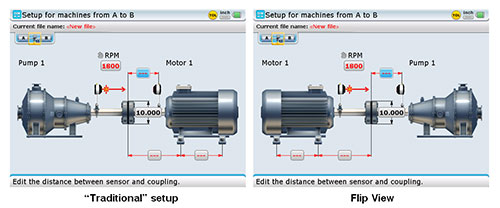

So, let’s just amend our setup statement a bit: I always say “LLLaser on the LLLeft and RRReceiver on the RRRight!” (or RRReflector, as the case may be.) This will help you to remember and keep your setups consistent. But what if your pump and motor are mounted close beside a wall, and you can only access the machines from one side? As luck would have it, that side is always “the wrong side” as dictated by Murphy’s law, with your pump on the right and the motor on the left, instead of the way you are used to seeing them. No matter! Still, mount your laser on the left machine. Now, since the Rotalign and Optalign want to move the right machine by default, you can now employ the “Flip Machines” feature, which will automatically swap the view of your machines left and right, so you can see them the way they really are in the field, and easily move the left machine now, even if you have mounted your laser on it.

If you have two equally hard-to-move machines, each of which you would ordinarily like to consider stationary (such as a heavily piped little steam turbine driving a heavily piped compressor), then it really just boils down to which machine (or combination of feet on both machines) is the most expedient to move. Again, mount the laser on the left. You can always use the static feet function to declare the machine on the right stationary and make the machine on the left movable or ask the tool to make any combination of feet movable so as to find your smallest possible moves or optimal combination of moves to solve bolt-bound or base-bound situations in the field. The ROTALIGN ULTRA products are especially versatile for this, since they let you explore fully optimized centerlines (move ALL the feet in the train), as well as under-constrained and over-constrained centerlines, to cope with the exigencies of the situations you encounter in the field.

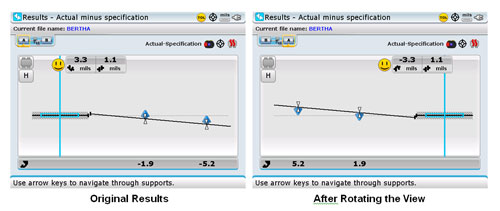

Lastly, if you ever need to compare your alignment or your target specs to a drawing or to someone else’s report that shows the machines the other way around from the way you set up, you can always use the Rotate View functionality to look at your results from the other side. You use this feature “after the fact”—in other words, after your setup is already complete, with readings taken and results obtained, you can always rotate the view and see your results as if you had walked around to the other side of the machines.

To summarize, the concept of “stationary” and “movable” is history. Use the Flip View feature right at the beginning, when you set up, to make your setup conform to the actual situation in the field. Use the Static Feet Function to make any machine movable or stationary, and to explore “best possible” correction alternatives.

Lastly, use the Rotate View feature to look at your alignment differently, after it’s already done.

Learn how these features work in the ROTALIGN ULTRA, OPTALIGN SMART, and SHAFTALIGN® laser shaft alignment systems.

Filed under:

Alignment by Alan Luedeking CRL CMRP