Some weeks ago, a compressor manufacturer contracted us to perform ROTALIGN® ULTRA laser alignment training at their testing facility. During the training, the millwrights mentioned that they had a need to align the gearbox shaft to the compressor bores during the assembly process before the compressor shaft was installed. Since my ROTALIGN ULTRA also features the CENTRALIGN® ULTRA bore alignment option, I offered to train them on this interesting application.

The objective was to perform the alignment so that when the compressor shaft is put in, it is already within tolerance and the compressor is immediately ready to be tested. This means that the millwrights need to align the static centerline of the bores of the compressor to the rotating centerline of the gearbox shaft. This is a challenging application that the ROTALIGN ULTRA with CENTRALIGN ULTRA can handle with ease (see Figure 1.)

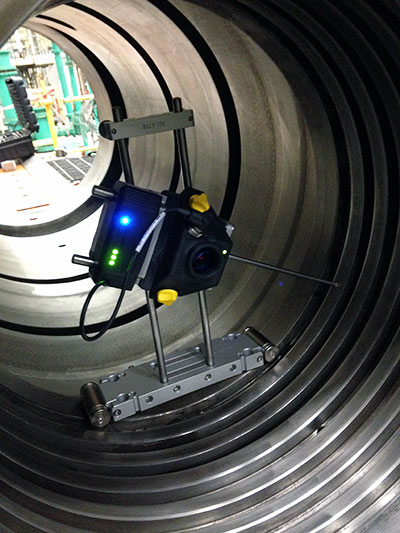

Fig. 1: Laser mounted on Rotating Gearbox Shaft

We first covered the key concepts of what it means to do a bore alignment. Hands-on exercises illustrated the differences between aligning with a static laser beam through the bores and a rotating laser setup on the gearbox shaft. Once on the shop floor, we were able to measure a compressor’s bores with respect to the gearbox shaft within 45 minutes, start to finish including setup time for both stages of the measurement (see Figure 2.)

Fig. 2: Receiver with Bluetooth module in compressor bore

The millwrights seemed thrilled with the simplicity of the process, compared to their current approach, which involved using a complicated bracket system to support dial indicators, sometimes taking up to a day to obtain accurate measurements.

The customer purchased the ROTALIGN ULTRA with CENTRALIGN ULTRA option and now obtains accurate and repeatable measurements within an hour, without depending on the skill level of the operator. This has freed up manpower, save time, and a great deal of money during the compressor assembly process.

Filed under:

Alignment by Adam Stredel CRL