Recently our customer, Metropolitan Sewer District of Greater Cincinnati (MSD), shared with us their successful findings with OPTALIGN SMART. Their Maintenance Department utilizes a variety of predictive technologies and preventive strategies to support their mission of improving equipment reliability and reducing downtime.

They are committed to extending the life cycles of their assets with their already established laser alignment program.

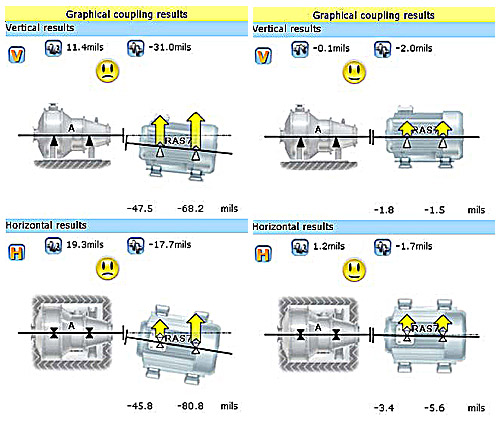

Their recent analysis started when their Maintenance Crew Leader downloaded and interpreted the alignment test results. Planned scheduled follow-up work orders, baseline testing, realignment, and retesting revealed that one of their pumps showed excessive shaft misalignment between the pump and motor in both the horizontal and vertical planes. As-found test results showed the equipment out of vertical alignment by 11.4 thousandths, and horizontal alignment off by 19.3 thousandths. The maintenance staff proceeded to generate a follow-up work order to realign the pump and motor.

Follow-up Actions:

Plant Maintenance Workers uncoupled and realigned the components, using jacking lugs and shims to correct the misalignment. After realignment work was completed, they installed a new coupling and performed follow-up retesting with the OPTALIGN SMART tool, verifying that the components had been aligned within the required specifications.

They have now proven that equipment misalignment will cause mechanical seal failure and premature bearing wear, resulting in equipment failure and unexpected downtime. By testing and aligning equipment proactively, MSD Maintenance personnel were able to identify and correct misalignment problems before irreversible damage occurred and assets would have had to be replaced. The total work order cost for testing and realigning this asset was $154.70. The purchase price of a new pump of this type is $2,456.00, resulting in a minimum cost avoidance of $2,301.30, not including labor costs to remove and reinstall the equipment.

Special thanks to our friends at Metropolitan Sewer District of Greater Cincinnati for sharing their success with us and reminding us once again that there are just No Excuses for Misalignment.

Filed under:

Alignment, Articles and Case Studies by Yolanda Lopez