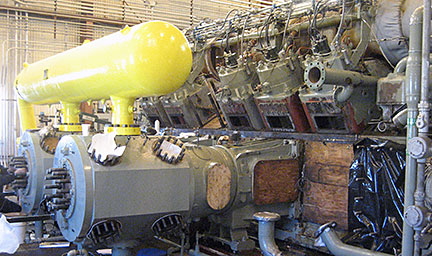

The bore alignment of the crosshead guides in a large compressor driven by a 4, 000 HP engine was thought to be a problem after this compressor, which had run trouble-free for 30 years started having problems. Methods used before involved checking with a machinist’s level only. The crosshead guides have an approximate diameter of 20”.

The bore alignment of the crosshead guides in a large compressor driven by a 4, 000 HP engine was thought to be a problem after this compressor, which had run trouble-free for 30 years started having problems. Methods used before involved checking with a machinist’s level only. The crosshead guides have an approximate diameter of 20”.

The ROTALIGN® ULTRA laser shaft alignment system with CENTRALIGN® ULTRA bore alignment add-on module was brought in and five cylinders were checked. Each cylinder to crosshead guide measurement took about 1 hour to complete, including setup and measurement. Most fell within five-thousandths of an inch of offset. One cylinder and crosshead guide were found to be out of alignment. This cylinder was measured to be lower than the crosshead guide by 70 thousandths and 65 thousandths at the inboard and outboard ends respectively. This result could not have been measured with the machinist’s level. Also, with the level no ability to check side-to-side misalignment exists.

Some wear was detected, so we were able to avoid the “bad” spots with the CENTRALIGN pointer bracket.

Repeatability was typical, at under 0.5 thousandths. The low Standard Deviation (SD) values provided by the ROTALIGN confirmed that measurements were not hitting damaged sections and were highly reliable. SD is not available with tight wire measurements, which can lead to having incorrect center readings. In addition, obstructions and confined spaces make tight wire setup and readings extremely difficult.

The ROTALIGN ULTRA with CENTRALIGN helped reveal problems with 100% confidence in measurements and with excellent repeatability, in a fraction of the time that would otherwise have been required using other, less accurate and less reliable methods. This resulted in great savings for the customer.

Filed under:

Alignment by Daus Studenberg CRL