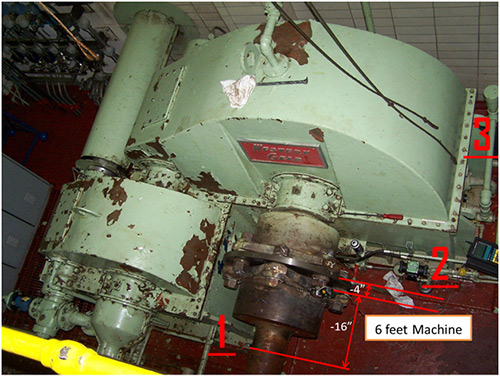

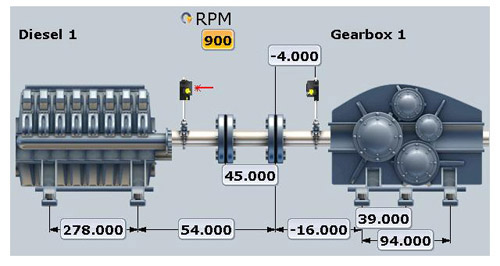

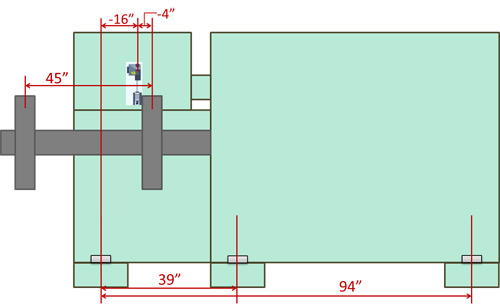

Laser shaft alignment has become ubiquitous these days. And for the most part, alignments are very similar from one machine train to another. The user enters the RPM for tolerance evaluation, enters the dimensions of the driver, measures misalignment, and makes corrections. But what happens when an unusual physical configuration exists, as when the foot of the machine is between the flex planes of the coupling? Or the receiver cannot be mounted outboard of the flex planes of such coupling?

Entering a dimension correctly as a negative value can take care of that problem. This will ensure that the corrections at the feet are precise, and the alignment is done properly.

Does your laser alignment system have this crucial capability? Our ROTALIGN® ULTRA laser alignment system does!

Filed under:

Alignment, Maintenance Tips by Adam Stredel CRL