What if you could reduce machinery alignment time from 4 hours to 2 hours? What if you could improve the average alignment from 9 mils to 3 mils? What if your Meantime Between Failure (MTBF) could be increased from 30 to 34 months, 13% (very conservative)?

What if you could reduce machinery alignment time from 4 hours to 2 hours? What if you could improve the average alignment from 9 mils to 3 mils? What if your Meantime Between Failure (MTBF) could be increased from 30 to 34 months, 13% (very conservative)?

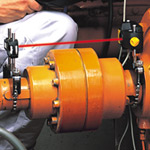

Consider this: A plant with 200 machines at an average of 30 HP and a Mean Time Between Failure (MTBF) of 30 months are aligned using dial indicators. With the same conditions and a ROTALIGN® ULTRA or OPTALIGN® SMART laser alignment tool, the following savings could be expected to occur:

- Power: $7, 125

- Repair Costs: $18,823

- Labor: $15,040

A total of over $40,000 per year!!!

Contact us today to see how Laser Alignment can increase reliability and productivity at your shop or to request your Return On Investment Study.

Filed under:

Alignment by Ana Maria Delgado, CRL