The following tips are ideas to consider for when “the going gets tough”, meaning that problems like residual soft foot, “bad geometry”, or becoming bolt-bound impede your ability to easily obtain an excellent alignment. But first, a few definitions:

- Residual soft foot: More soft foot than you are comfortable with, but can’t do anything about. Can be caused by problems like slightly angled feet or a bit of pipe strain.

- Bad geometry: Equipment where the distance from the coupling center to the front feet is equal to or greater than the distance from the front feet to the back feet.

- Becoming bolt-bound or base-bound: When alignment corrections can’t be made because you have run out of room in the anchor bolt holes in the feet, or have to come down but have no shims left under the feet to remove.

Final Vertical Misalignment Correction (Horizontal Misalignment already close)

1. Position front feet close to offset tolerance. Finish the alignment by moving the rear feet only.

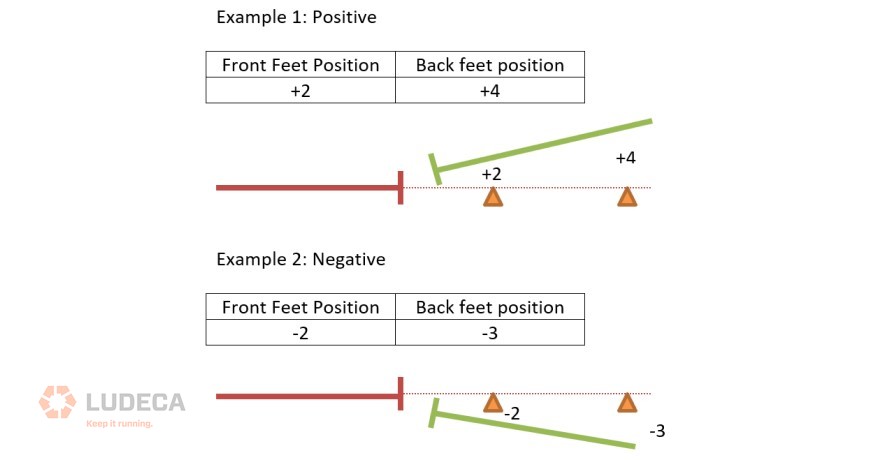

2. Final foot positioning should make offset at the coupling center decrease. To achieve this, position feet as shown in the below example:

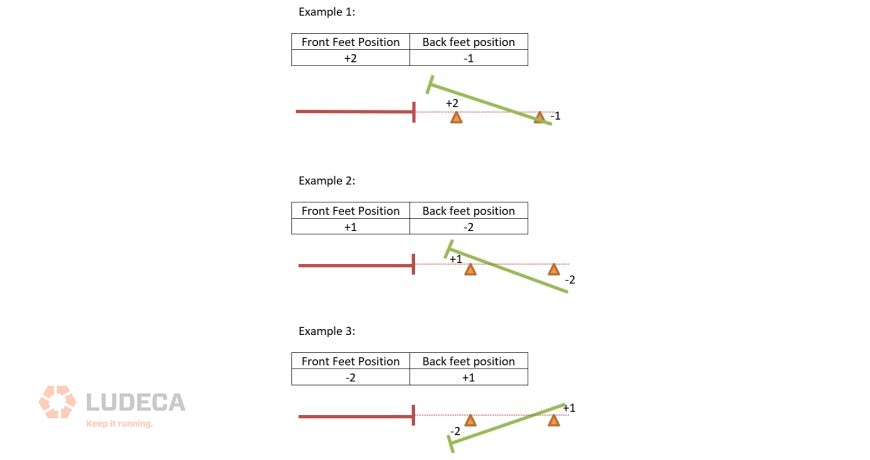

3. One must avoid leaving feet positioned with opposite signs, even if the values are very small. Below is an example:

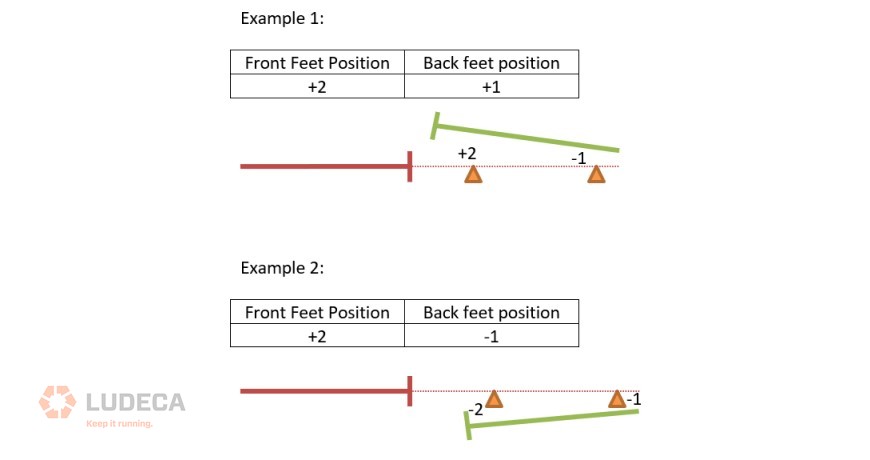

4. One must also avoid allowing the position value of the front feet to be higher than the back feet value, even if they have the same sign. Shown below.

Notes:

- The above rules apply to horizontal corrections as well.

- Remember to torque the anchor bolts on small equipment in steps.

Watch our Shaft Alignment Know-How: What’s Misalignment video to learn the causes and effects of having misalignment in your rotating equipment.

Filed under:

Alignment, Maintenance Tips by Carlos Bienes CRL