Thermal Growth and Pipe Stress: Preventing Machine Failures with Dynamic Measurement

In industrial machinery, thermal growth and pipe stress are significant factors that can lead to unwanted movement and eventual machine failure. When machinery heats up, it expands. This thermal growth, if unmonitored and uncorrected, can lead to misalignment and stress in the machine casing. This stress can cause the machine to move or alter its designed geometry, leading to internal and external misalignment, leakages, and potentially catastrophic failures.

Understanding Dynamic Measurement

Dynamic measurement is the key to identifying and correcting these issues before they lead to machine failure. This method tracks unwanted movements caused by various forces, including thermal growth, pipe stress, and additional heavy loads. By detecting and documenting these movements, dynamic measurement ensures the machine operates within its designed parameters, maintaining optimal performance and preventing downtime.

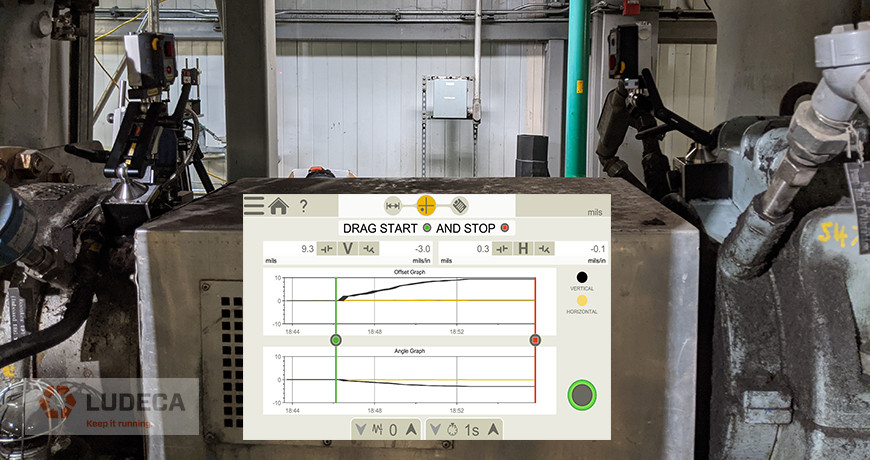

Easy-Laser® EasyTrend™ Application

EasyTrend, a specific application used with the Easy-Laser XT770 laser alignment tool, excels in measuring and recording any movements of rotating machinery in real-time. This application captures angle and offset movements in both horizontal and vertical axes, providing a comprehensive picture of the machine’s behavior under operational conditions. By setting recording intervals to desired times, EasyTrend offers detailed documentation for future reference and troubleshooting.

When to Perform Dynamic Measurements

To ensure reliable machinery installation and prevent costly downtime, dynamic measurements should be conducted during the Site Approval Test (SAT) before starting operations. Additionally, these measurements should be repeated every time the equipment undergoes overhaul and reinstallation. This proactive approach guarantees that any potential issues related to thermal growth and other forces are identified and addressed promptly.

The Role of Pipe Stress

Pipe stress is another critical factor to consider. There are two types of pipe stress: static and dynamic. Static pipe stress occurs when the pipe flange is misaligned to the inlet or discharge flange due to poor assembly procedures or inadequate pipe support. Dynamic pipe stress happens during system operation and results from thermal expansion, weight, pressure of the media or fluid, and inadequate pipe support. Both types of pipe stress can cause significant strain on machinery, leading to misalignment and potential failure.

Benefits of Using Easy-Laser® DM Brackets

For accurate dynamic measurements, Easy-Laser DM Brackets are essential. These brackets, when mounted on the machinery, enable precise measurement of movements. The kit includes both glue-on and bolt-on attachment plates to suit various applications. After measurements are completed, the brackets can be easily removed, ensuring minimal impact on the machinery.

By leveraging Easy-Laser’s advanced dynamic measurement tools and applications, industries can effectively manage thermal growth and pipe stress, ensuring their machinery operates smoothly and efficiently, thus avoiding costly failures and downtime.