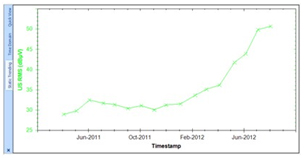

The basic concept of CBM (Condition Based Maintenance) is to monitor the condition (CM) of a machine over time and use conditional data to predict the need for maintenance to take action (PdM). Let’s apply this concept to the re-lubrication of rolling element bearings.

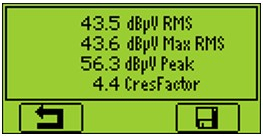

Using an SDT ultrasound instrument (simple or advanced), lube-techs collect data that indicates the current condition of the bearing. What are some of the Condition Indicators collected by SDT? Simple “STATIC” Condition Indicators. Ultrasound STATIC data provides an instantaneous snapshot of bearing condition.

- RMS – The average of the ultrasound signal over the duration of the measurement time

- Max RMS – The highest RMS signal observed over the duration of the measurement time

- Peak – The highest amplitude observed over the duration of the measurement time

- Crest Factor – A linear ratio between the Peak and the RMS (CF=Peak/RMS)

Use the RMS condition indicator to determine lubrication intervals and guide you while slowly applying grease to a bearing. For example:

Use the RMS condition indicator to determine lubrication intervals and guide you while slowly applying grease to a bearing. For example:

- Correctly greased: RMS = 35.2 dBµV

- Under-greased: RMS = 45.8 dBµV

Filed under:

Ultrasound by Allan Rienstra - SDT Ultrasound Solutions