Sometimes I will assist a customer on-site for shaft alignment. The first thing I will ask is, “what is the tolerance you wish to achieve?” Many times I would be given a specification, but sometimes I would be told “we need it aligned to 1 thou.” 1 thou I would ask, where? The answer would be “at the coupling and feet.” I would then reply, “Well that depends…”

Assuming soft foot will be addressed and that correct targets (deliberate misalignment, if needed) are given, there is just one thing that needs to be aligned. That is both shafts. They should be set for a proper offset and angle at the coupling point.

Watch our Shaft Alignment Know-How: Offset & Angularity and learn about the concepts of Offset & Angularity as they relate to aligning rotating equipment.

Feet adjustments are what you move the machine to align it to achieve tolerance at the coupling, therefore, feet moves have no tolerance. Feet adjustments vary depending on how far away or near they are to the coupling and to each other. Think of a laser pointer. If you aim it at a wall close to you and slightly angle it, the beam will slightly move. Should you aim in 20 feet away and slightly angle it, it moves much more. Depending on the feet positions, the precision of the adjustments will be generally more critical if they are closer together than if they are farther apart.

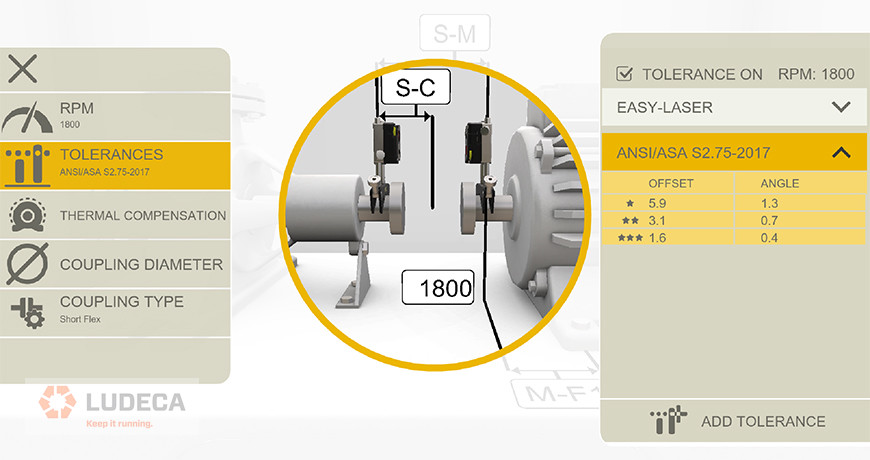

Regarding the coupling, the most important part of the alignment, you should consult your alignment tolerance table. For example, see the Easy-Laser XT’s built-in ANSI tolerance table below:

To achieve excellent (***) tolerance for coupling offset, you need to be within +/- 1.6 thou. Being within +/-1 thou can mean achieving either -1.0 thou or +1.0 thou, which is still within the excellent tolerance of +/- 1.6 thou. Being within +/- 1 thou offset at the coupling also means that you are within acceptable (**) and minimal tolerance (*) standards.

It is an entirely different case for the angle. The excellent tolerance is 0.4 thou/in, the acceptable is 0.7thou/in and the minimal is 1.3 thou/inch. 1 thou of variation can throw the alignment angle at the coupling completely out of alignment! Now is the spec unreasonably tight? Absolutely not! It is expressed in thou/in. If you had a typical 10” coupling, 1 thou out is equivalent to a coupling gap of 10 thou out, and this gets magnified for large couplings!

In conclusion, be careful about following the dogma of “1 thou” being acceptable. It is important to follow your required tolerance specifications.

Request your complimentary copy of our Shaft Alignment Fundamentals Wall Chart which highlights the ANSI/ASA Shaft Alignment Tolerances as well as information and guidelines for the implementation of good shaft alignment of rotating machinery, best practices, soft foot, tolerances, thermal growth, and much more!

Filed under:

Alignment by Daus Studenberg CRL