Belt alignment is extremely important, and we recommend you do it with a good laser alignment system such as the Easy-Laser XT190 or the DotLine Laser system.

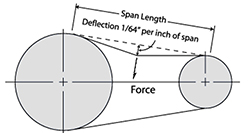

But, once the pulley alignment is done, equally important is to set the belts to the proper tension. Typically, the correct tension is one that allows the belt to be deflected on its tight side by a specified amount of force to an amount of 1/64th inch per inch of span length. The span length is the distance between the nearest points of contact of the belts on their sheaves. If this distance is not known, you can use the center distance between the pulleys; that’ll be close enough.

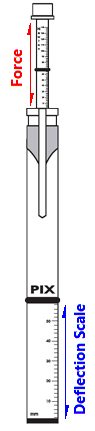

To do this, you use a spring tension gauge, which is a device that measures the amount of force that you apply to something when you push against it or pull on it.

So, say the span length of a given belt drive is 36 inches. You should deflect the belt (in a group of belts, usually the center one, but measure the two outside ones as well) by 36/64″, (or 9/16″) which is 1/64″ of deflection for every inch of span length, and measure how many pounds or newtons of force it takes to do that. This force should not be less (too loose) or more (too tight) than what the manufacturer of the belts recommends for that drive or for that set of belts. Also, you perform this test by pressing down with your gauge upon the belts in the middle of their span length on the “tight side” of the belts. The tight side of the belts is the side that is stretched as the drive turns and the driver pulley applies rotational force to the driven pulley. The return side is the slack side of the belts.

The recommended belt tension deflection forces are usually supplied in a table that takes into account the size, length, and type of belts, the number of belts in the drive, the anticipated application loads and drive ratios of the sheaves. Move the driver until the recommended force specification is met for the desired deflection, being careful not to mess up the sheave alignment while doing so!

Filed under:

Alignment, Maintenance Tips by Alan Luedeking CRL CMRP