Reposted from EASY-LASER® blog

There are basically two types of pipe strain: static and dynamic pipe strain. Static pipe strain occurs both when the machines are operating and when they’re not running. This is most likely the type you’ve been trying to eliminate. Dynamic pipe strain, on the other hand, is a condition that only takes place when the machines are operating.

PIPE STRAIN AND ALIGNMENT

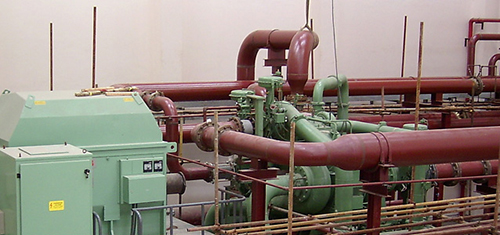

Strain, which is the deflection and positional change resulting from pipe stress, comes from the suction and discharge piping, and creates stresses on the machine frame or casing that in turn spread to the equipment body. A result of this is often a change in the alignment of the shaft. It also results in distortion of the machine casing which misaligns the bearings within the machine, resulting in very harmful vibration and increased radial loads on the bearings. So, before attempting shaft alignment, you should ensure that suction and discharge piping are not causing strain on your machines.

HOW CAN YOU CONTROL PIPE STRAIN?

Static pipe strain and its effects are fairly simple to control, and you can use any of the Easy-Laser® shaft alignment systems to measure the strain and help eliminate it. Here’s how: simply mount the system in the normal manner as when you perform the shaft alignment. Then:

- Position the measuring units at twelve o’clock. Use the Values program and set both units to zero.

- Rotate the shafts to the three o’clock position, and note if the values are not zero. Rotate the shafts back to twelve and confirm the zero setting.

- Now connect or disconnect the piping. Any changes to the values for the twelve and three o’clock positions is the result of pipe strain and should be corrected, which will require careful pipe fitting. What you are seeing is movement transmitted through the casing to the bearings and shaft.

Dynamic pipe strain is more difficult because it only occurs when the machines and piping are at operating conditions. And a good proportion of this type of pipe strain may be a consequence of the thermal expansion of the piping and the weight of the system fluid. This explains why the dynamic pipe strain is not a fixed state and why it might be difficult to handle.

We understand that this can be quite a challenge, however, we believe you have a lot to gain from minimizing dynamic pipe strain. And there are effective tools for this purpose: Our Easy-Laser measuring program has a great feature that registers measurement values automatically for a specified amount of time and frequency of measurement. This is very useful for looking at the differences between a machine that’s up and running and one that’s down. The data can also be transferred to the EasyLink™ software, where you can see the results more clearly, in the shape of a graph to scale.

IN CONCLUSION

The existence of pipe strain indicates that more than just alignment is needed for optimal machine performance; there are other important factors to take into consideration. This requires flexible measurement systems that will support you and help you reach your goal. You need more than a shaft alignment system; you need a total alignment solution.

We invite you to watch our Pipe Stress Know-How video to learn more about the effects of running equipment with pipe stress.

Filed under:

Alignment by Yolanda Lopez